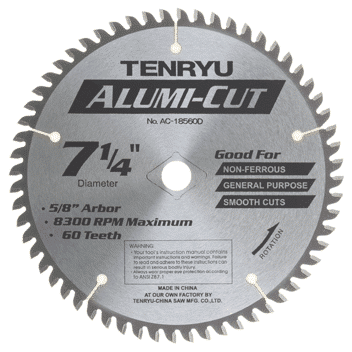

Tenryu Plastic Cutter Series

$399.90 – $1,399.90 Free Shipping

Experience superior plastic cutting with Tenryu Plastic Cutter Series, featuring innovative “no melt” carbide technology and precision-engineered thin kerf design. These specialized blades deliver exceptional performance across various plastic materials, preventing chipping and edge melting while maintaining cost-effectiveness. Now available with free shipping and quantity discounts.

Free Shipping!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

- Call 1-866-601-8105 For Bulk Discounts

Tenryu Plastic Cutter Series

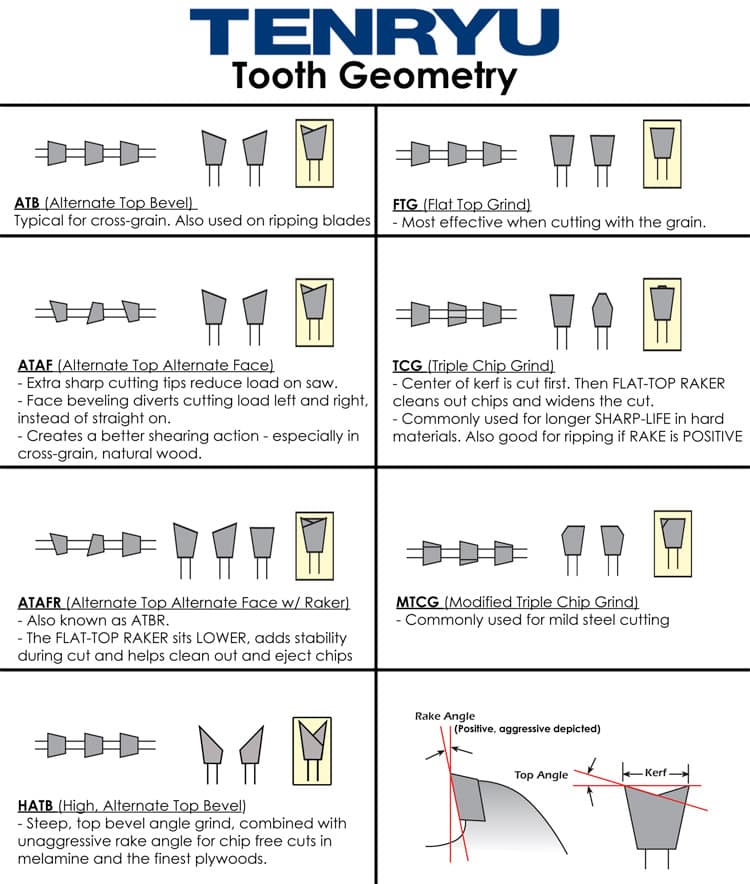

The Tenryu Plastic Cutter Series represents a breakthrough in plastic cutting technology, combining affordability with professional-grade performance. Each blade features individually hammer-tensioned steel plates and specially selected carbide grades optimized for plastic cutting. The unique tooth geometry and mirror-finished carbide tips work together to minimize heat buildup while maintaining exceptional cut quality in materials from PVC to acrylics.

Applications:

• PVC cutting

• Acrylic processing

• Sheet plastic fabrication

• Sign making

• Display manufacturing

• General plastic cutting

• Industrial fabrication

• Production work

Key Features:

• Design: No-melt grind pattern

• Construction: Selected-grade carbide

• Engineering: Hammer-tensioned plates

• Profile: Thin-kerf configuration

• Finishing: Mirror-polished carbide

• Performance: Heat reduction technology

• Precision: True-running accuracy

• Application: Multi-plastic capability

• Quality: Strict tolerance control

• Value: Economic efficiency

FAQs:

Q: What makes these blades special for plastics?

A: The “no melt” grind pattern and specialized carbide grade prevent heat buildup and edge melting.

Q: How do they prevent chipping?

A: Strict manufacturing tolerances and optimized tooth geometry minimize material chipping.

Q: What materials can they cut?

A: They excel in cutting PVC, acrylics, and various sheet plastics.

Q: What’s the benefit of the thin kerf?

A: It reduces material waste and heat generation while maintaining cut quality.

Q: How is the heat buildup controlled?

A: The specialized tooth geometry and grind pattern minimize friction and heat generation.

Q: Are these blades readily available?

A: While they may require short lead times, contact 1-866-601-8105 for current availability.

Q: What makes the carbide special?

A: It’s specifically selected and honed for optimal performance in plastic materials.

Q: How precise are the cuts?

A: The hammer-tensioned plates ensure true-running accuracy for clean cuts.

Q: Are bulk discounts available?

A: Yes, contact 1-866-601-8105 for volume pricing options.

| Size | 10'' X 80 TOOTH, 12'' X 100 TOOTH, 14'' X 100 TOOTH, 4'' X 36 TOOTH, 7 1/4'' X 60 TOOTH, CORDLESS 6 1/2'' X 60 TOOTH, CORDLESS 6'' X 56 TOOTH |

|---|

Reviews

There are no reviews yet.