Description

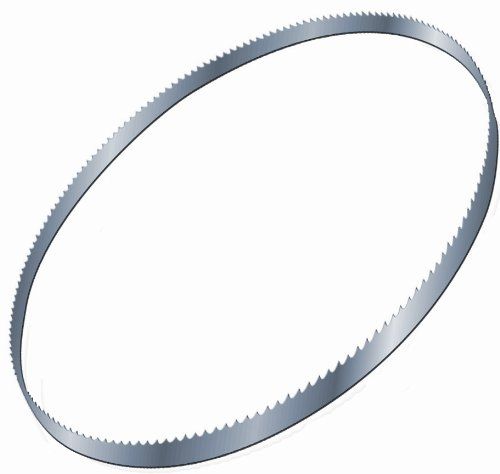

MORSE BI-METAL COMPACT MINI PORTABAND BLADES

These rugged, heat-treated M.K. MORSE BI-METAL COMPACT MINI PORTABAND BLADES are welded-to-length in our manufacturing plant. They install easily, last a long time, and smoothly cut a wide variety of materials with a cordless bandsaw. They are 32 7/8” long and come in 10 teeth per inch all the way to 24 teeth per inch with all variations.

FEATURES & BENEFITS

- M.K. MORSE BI-METAL COMPACT MINI PORTABAND BLADES – Shock-resistant teeth great for cutting machinable metals

- Variable pitch allows a broader range of applications and reduced vibration

- Special heavy duty SKU’s available in .025″ thickness

- Straight pitch teeth for better chip clearance and fast cutting

- Available in a variety of lengths for any portable saw on the market

- Heavy-duty .020 in. thickness

- Fits all brands of cordless portable band saws that use a 32-7/8 in. long blade

- Manufacturers link here

- See all of our blades here

APPLICATIONS Machinable metals including stainless steel, pipe, tubing, and solids

At the M. K. Morse company we`ve had just one focus for over fifty years. Moreover, to make better saw blades and accessories, and get them to customers on time. We don`t make machinery and other products. We do one thing and we do it well. Single-minded devotion has led to some unique innovations over the years. Mostly it has led to a relentless march to improve value. However, we are constantly looking for ways to build even more durability into our blades.

The result is a collection of high value blades that top the charts in performance and quality. These blades are used by industrial, construction, and demolition companies worldwide. Our state-of-the-art manufacturing plant is totally integrated. This unique ability to control our process makes it easier for us to meet tight production deadlines and control costs. Our customers get benefits. At M. K. Morse this is the way to operate.