Tenryu Mel Pro Series

Price range: $699.95 through $1,299.95 Free Shipping

Master melamine and veneer cutting with Tenryu Mel-Pro Series, the result of extensive research and development in precision blade engineering. Featuring micro-grain carbide teeth and innovative vibration-dampening technology, these blades deliver chip-free cuts and exceptional longevity. Experience world-class performance with reduced noise and minimal bottom-side blowout, now available with free shipping and quantity discounts.

Free Shipping!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

- Call 1-866-601-8105 For Bulk Discounts

Tenryu Mel Pro Series

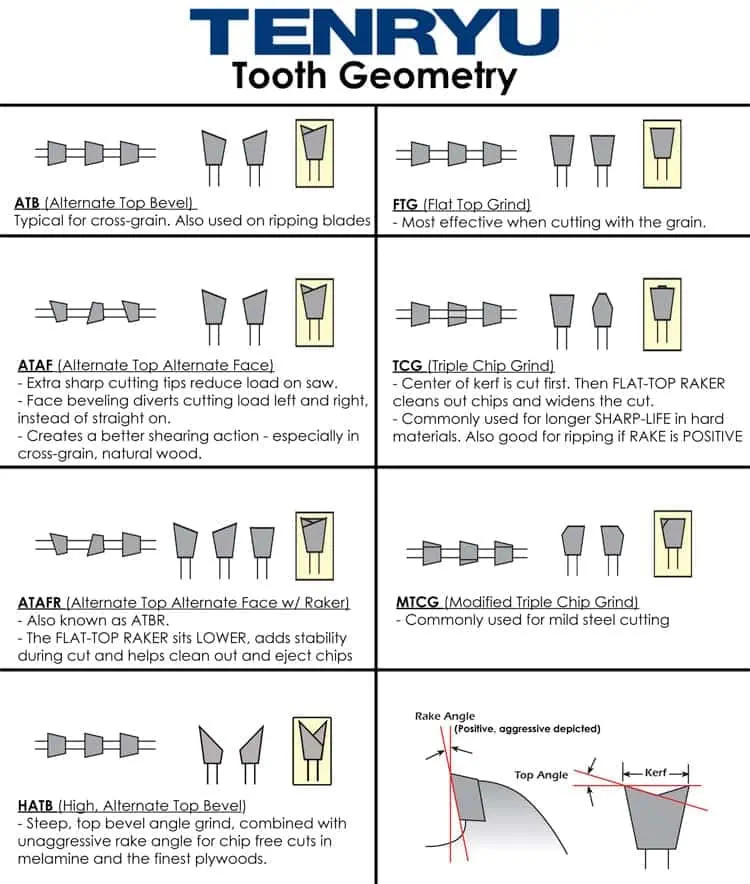

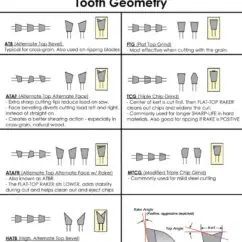

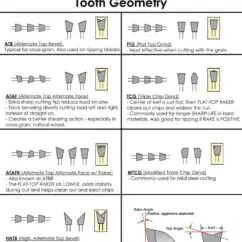

The Tenryu Mel-Pro Series represents a breakthrough in laminated material cutting technology. Each blade combines a fully hardened, expertly tensioned tool steel body with exclusive red bond resin-filled expansion slots for superior vibration control. The ATAFR (Alternate Top Alternate Face with Raker) design and mirror-finished carbide tips work together to deliver exceptionally clean cuts while maintaining superior durability in demanding applications.

Applications:

• Melamine processing

• Veneer-faced plywood

• Laminated materials

• Cabinet manufacturing

• Furniture production

• Professional woodworking

• Fine finishing

• Production cutting

Key Features:

• Construction: Micro-grain carbide teeth

• Design: ATAFR tooth geometry

• Technology: Red bond resin slots

• Profile: Thin-kerf configuration

• Engineering: Expert hand tensioning

• Performance: Anti-corrosive coating

• Operation: Noise reduction system

• Efficiency: Reduced heat buildup

• Quality: Mirror-finish grinding

• Application: Melamine specialist

FAQs:

Q: What makes this blade special for melamine?

A: The combination of micro-grain carbide and ATAFR grind provides chip-free cuts with minimal blowout.

Q: How does the noise reduction work?

A: Exclusive red bond resin-filled slots absorb vibration for significantly quieter operation.

Q: What’s the advantage of the thin-kerf design?

A: It reduces cutting resistance and heat buildup while maintaining precision.

Q: How long do these blades typically last?

A: The anti-corrosive carbide teeth provide extended life against both chemical and abrasive wear.

Q: What makes the tensioning special?

A: Expert hand tensioning ensures the blade remains flat and true during operation.

Q: Can these handle production speeds?

A: Yes, they’re designed for reasonable feed speeds while maintaining cut quality.

Q: How does it prevent bottom-side blowout?

A: The precision-ground teeth and specialized geometry minimize material tearout.

Q: What’s the benefit of the mirror finish?

A: It reduces friction and heat buildup while improving cut quality.

Q: Are bulk discounts available?

A: Yes, contact 1-866-601-8105 for volume pricing options.