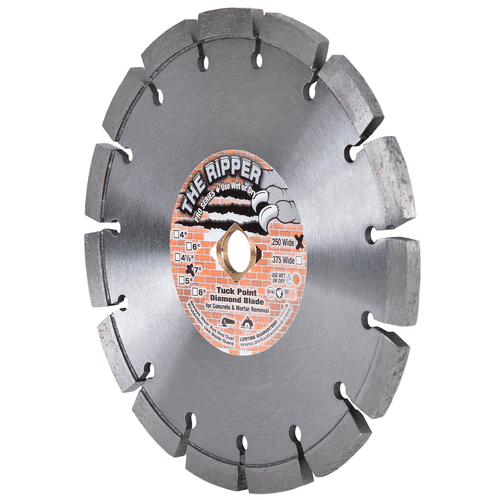

Ripper .250 Tuck Point Blades

The Ripper .250 Tuck Point Blades are engineered with premium laser-generated GE Super-abrasive diamond segments, providing optimal cutting speed and efficiency. Whether you’re removing mortar, repairing grout, or preparing masonry and concrete surfaces, these blades deliver clean, precise cuts with minimal effort. The advanced diamond technology ensures that each cut is smooth and accurate, reducing the need for rework and enhancing overall productivity.

Crafted for longevity, the Ripper .250 Tuck Point Blades feature extra-tall 10-millimeter diamond segments that offer superior cutting stability and extended blade life. This robust construction allows the blades to withstand heavy use without compromising performance, making them a cost-effective alternative to high-priced big-name brands. The meticulous design ensures that each blade maintains its integrity, providing consistent results even in the most demanding work environments.

Designed with versatility in mind, these blades come with a standard arbor size that fits most grinders, hand-held grinders, and circular saws. Whether you’re using a portable saw for crosscutting or a slide-miter saw for precise angles, the Ripper .250 Tuck Point Blades seamlessly integrate into your existing toolkit. Their adaptability allows for both wet and dry cutting applications, catering to a wide range of project requirements.

Delta’s innovative ATAF shear face grind technology ensures fast and long-lasting cuts while minimizing drag. Additionally, the resin-filled laser-cut body slots act as built-in dampeners, significantly reducing vibration and noise during operation. This not only enhances the user experience but also extends the lifespan of the blade by preventing excessive wear and tear.

The Ripper .250 Tuck Point Blades are ideal for a variety of applications, including:

- Mortar and Grout Removal: Quickly and efficiently remove mortar and grout from masonry and concrete surfaces.

- Masonry Repair: Perfect for repairing joints in stone or brick masonry walls, ensuring structural integrity and aesthetic appeal.

- Concrete Preparation: Prepare concrete surfaces for further construction or finishing work with precision and ease.

- Industrial Uses: Suitable for applications in wastewater treatment plants, subway tunnels, and other industrial settings that require reliable and durable cutting solutions.

Key Features

- Premium Diamond Segments: Features advanced GE Super-abrasive diamond segments for optimal cutting speed and efficiency.

- Extra-Tall 10mm Segments: Enhanced cutting stability and extended blade life for long-lasting performance.

- Unique ATAF Shear Face Grind: Ensures fast, clean, and precise cuts with minimal drag.

- Dampened Laser-Cut Plate: Incorporates resin-filled slots to reduce vibration and noise during operation.

- Hand-Hammered Plate Tensioning: Provides a flatter blade and truer cuts for superior accuracy.

- Durable Construction: Made by Delta, a leading Diamond Blade Manufacturer with over 30 years of experience.

- Versatile Compatibility: Standard arbor size fits most grinders, hand-held grinders, and circular saws.

- Wet or Dry Use: Designed for flexibility, allowing use in both wet and dry cutting applications.

- Chip-Free Performance: Delivers clean, burr-free cuts on melamine and other laminates, even on two-sided cuts.

- Affordable Pricing: Offers premium quality at a fraction of the price of major brands.

- Bulk Packaging Available: Sold in convenient box pricing of 10 blades per box with free shipping.

- Comprehensive Applications: Ideal for mortar and grout removal, masonry repair, concrete preparation, and industrial uses.

- Satisfaction Guarantee: Backed by a 100% Satisfaction Guarantee, ensuring confidence in the blade’s performance and reliability.

FAQs

Q: What materials can the Ripper .250 Tuck Point Blades effectively cut?

A: The Ripper .250 Tuck Point Blades are designed to cut and chase cracks in cured concrete, asphalt, stone, and brick masonry walls. They are also excellent for mortar and grout removal, preparing masonry and concrete surfaces, and can handle non-ferrous metals, plastics, and solid surface materials with ease.

Q: Are these blades compatible with all types of saws?

A: Yes, the Ripper .250 Tuck Point Blades feature a standard arbor size that fits most hand-held grinders, hand-held grinders, and circular saws. This universal compatibility makes them versatile and easy to integrate into your existing toolkit without the need for multiple dedicated blades.

Q: How durable are the Ripper .250 Tuck Point Blades?

A: These blades are built to last, featuring premium laser-generated diamond segments and extra-tall 10mm diamond segments that enhance cutting stability and extend blade life. The high-quality GE Super-abrasive diamond material ensures optimal cutting speed and efficiency, providing long-lasting performance even under heavy use.

Q: Can these blades be used for both wet and dry cutting?

A: Yes, the Ripper .250 Tuck Point Blades are designed for versatility and can be used in both wet and dry cutting applications. This flexibility allows you to adapt to different working conditions and project requirements, ensuring optimal cutting performance in various environments.

Q: What is the warranty or satisfaction guarantee for these blades?

A: The Ripper .250 Tuck Point Blades come with a 100% Satisfaction Guarantee. If you are not completely satisfied with your purchase, please contact our customer service team for assistance. We are committed to ensuring that you receive high-quality products that meet your expectations.

Q: How do the resin-filled laser-cut body slots benefit the blade’s performance?

A: The resin-filled laser-cut body slots act as built-in dampeners, significantly reducing vibration and noise during operation. This not only provides a quieter cutting experience but also enhances blade stability, resulting in truer and more accurate cuts while prolonging the blade’s lifespan by preventing excessive wear.

Q: What is the difference between the 1/4″, 3/8″, and 1/2″ widths available?

A: The different widths—1/4″, 3/8″, and 1/2″—allow you to choose the blade that best suits your specific cutting needs. Wider blades like the 1/2″ are ideal for faster and more aggressive cutting, while narrower blades like the 1/4″ offer more precision for detailed work. This variety ensures that you have the right blade for any project size and complexity.

Q: How should I maintain and store the Ripper .250 Tuck Point Blades?

A: To ensure optimal performance and longevity, keep the blades clean from debris after each use. Regularly inspect the blades for any signs of wear or damage, and store them in a dry, protected environment to prevent corrosion and maintain their sharpness and structural integrity.

Q: Are these blades suitable for industrial applications?

A: Yes, the Ripper .250 Tuck Point Blades are well-suited for industrial applications such as wastewater treatment plants, subway tunnels, and other demanding environments. Their durable construction and versatile cutting capabilities make them a reliable choice for various industrial tasks that require precision and durability.

Q: Where can I purchase the Ripper .250 Tuck Point Blades in bulk?

A: For bulk purchases of the Ripper .250 Tuck Point Blades, including box pricing of 10 blades per box with free shipping, please contact us directly at 1-866-601-8105. You can also purchase these blades in bulk through our website, where you can explore our full range of diamond blades and find the perfect fit for your projects.

Reviews

There are no reviews yet.