Quick Change Surface Prep Discs

Price range: $179.00 through $299.00 Free Shipping

Sold by the Case of 100 at the best price online!

Elevate your sanding efficiency with our Quick Change Silicon Carbide Super-fine Surface prep Discs, specifically designed for optimal use on die grinders, air grinders or power drills.

Ideal for grinding welding seams, smoothing surfaces, and achieving a contaminant-free finish, they provide exceptional durability and a great cut rate to cost ratio, making them a must-have for professionals and DIY enthusiasts alike.

Made by Continental Abrasives. Trusted by Generations. World Class Performance. Best Value. These are the Best Prices online for these discs!

These are Premium Grade & Super-Fine Grit.

Available in 2” or 3”

Call us to mix & match sizes!

Free Shipping!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

- Call 1-866-601-8105 For Bulk Discounts

Quick Change Surface Prep Discs

These Quick Change Silicon Carbide Super-Fine Surface Prep Discs are expertly crafted for superior performance in deburring, leveling, finishing, and more and are the best super fine ones on the market. They feature Supreme-grade Silicon Carbide on a nylon surface that exceed ANSI and EU European standards to act as a rust remover for metal.

These Surface Prep Discs are made for easy quick-change use on Die Grinders, Air grinders and power drills. They are Fine grit to leave a super smooth finish. These discs are absolutely perfect for any job!

These flexible non-woven Surface Prep Discs are not only perfect for grinding welding seams, but they also excel at surface finishing and deburring. These discs enhance the overall quality of your work. Whether you’re polishing surfaces or performing intricate work, these discs guarantee rapid stock removal with high efficiency.

Designed with durability in mind, these Surface Prep Discs offer an excellent cut rate to cost ratio, making them a cost-effective investment for various applications. They can be easily attached and detached using a quick change mechanism, which significantly speeds up the sanding process.

Sold by the case (100 discs), they come backed by Continental Abrasives’ satisfaction guarantee, ensuring you can buy with confidence. If you’re not completely satisfied with your order, simply call 1-866-601-8105 for easy returns.

Key Features:

- Type: Quick change sanding discs

- Material: Silicon Carbide for a Super-Fine finish

- Applications: Ideal for heat-sensitive alloys like stainless steel, nickel alloys, and titanium

- Performance: Excellent for grinding welding seams and smoothing surfaces

- Contaminant-Free: Provides a clean sanding output

- Cut Ratio: Superior cut rate to cost ratio

- Product Line: Continental Abrasives

- Pricing: Sold by the case (100)

- Shipping: Free shipping available for orders

Pricing (Sold by the Case of 100):

- 2” Aluminum Oxide Fine grit, Box of 100: $179.00 ($1.79 per disc) w/ Free Shipping!

- 3” Aluminum Oxide Fine grit, Box of 100: $299.00 ($.2.99 per disc) w/ Free Shipping!

Note: Sold in Cases but, to mix & match a box, Or for Quantity Discounts, Call us at 1-866-601-8105

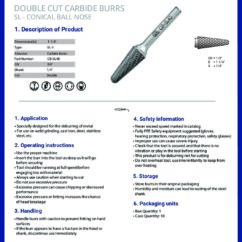

Operating instructions:

- Select the correct surface prep discs type and grit for your material and application.

- Inspect the surface prep discs for cracks, tears, broken flaps, or other visible damage before use.

- Ensure your machine’s maximum RPM does not exceed the maximum RPM listed on these surface prep discs.

- Disconnect the power source before installing the surface prep discs.

- Mount the surface prep discs securely on the machine, using the correct tightening mechanisms and ensuring proper centering.

- Tighten the discs according to the manufacturer’s instructions.

- Test run the sander / grinder at full speed in a safe area for at least 60 seconds before applying to the workpiece.

- Use light, consistent pressure and move the tool in smooth strokes across the surface.

- Do not force the surface prep discs into the material; let the abrasive do the work.

- Avoid prolonged sanding in one spot to prevent overheating and rapid wear.

- Allow the machine and belts to come to a complete stop before setting it down or changing belts.

Handling:

- Store surface prep discs in their original packaging in a dry, cool place away from moisture and sunlight.

- Avoid stacking heavy objects on top of these discs to prevent warping or damaged flaps.

- Handle discs carefully to avoid impacts or drops that could cause hidden damage.

- Always check for any signs of warping, cracks, or loose abrasive before use.

- Keep discs flat during storage and prevent contact with oils, solvents, or corrosive substances.

Safety information:

- Always wear ANSI-approved eye protection, hearing protection, gloves, and a dust mask or respirator suitable for the material being ground.

- Use only with properly installed and functioning safety guards on your machine.

- Ensure the workspace is clean, dry, and free of flammable materials. Keep bystanders at a safe distance.

- Never exceed the recommended RPM for the installed zirconia PSA discs.

- Do not use these discs for applications other than their intended use.

- Replace the disc immediately if you notice excessive vibration, noise, wear, or visible damage during operation.

- Follow all manufacturer and tool safety instructions and dispose of used or damaged zirconia PSA discs according to local regulations.

FAQs:

Q: What materials are these Surface Prep Discs suitable for?

A: These discs are excellent for use on heat-sensitive alloys, including stainless steel, nickel alloys, titanium, and more.

Q: How do Silicon grains benefit these discs?

A: Silicon grains run cooler than aluminum oxide and zirconia grains, reducing heat buildup and preventing damage to heat-sensitive materials.

Q: What are the primary uses of these Surface Prep Discs?

A: These discs are ideal for grinding welding seams, surface finishing, deburring, and producing a contaminant-free output.

Q: How do the quick change features work?

A: The quick change feature allows for fast and easy attachment and detachment of the discs, facilitating a more efficient workflow.

Q: Is free shipping available on these Surface Prep Discs?

A: Yes, we offer free same-day shipping on all orders!

Q: Is there a satisfaction guarantee available with these Surface Prep Discs?

A: Yes, NIS Tools guarantees satisfaction with every purchase and offers support for returns if needed.

Check out ALL of our Abrasives

| Size | 2'', 3'' |

|---|